Thermal Evaporation

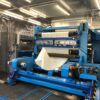

During thermal evaporation, the wire-shaped coating material is continuously fed onto resistance-heated crucibles. The wire first liquefies and then passes into the gas phase in the form of a vapour cloud. The substrate to be coated is guided over a rotating, cooled roller, which is positioned just above the crucibles. Thus, the coating material evaporates onto the substrate, where it condenses and forms the desired layer.

Deliverables

Specifications and Deliverables

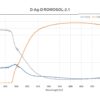

The wire speed and the temperature of the crucible can be used to set the evaporation rate and, in conjunction with the substrate's web speed, the desired coating thickness.

Value Proposition

Experimental runs and production volume possible

Contact Listings Owner Form

Premium Members see more!

- Learn about who has visited this offer

- Get funding opportunities matching this technology

- Get detailed access statistics as listing owner